Selected Examples

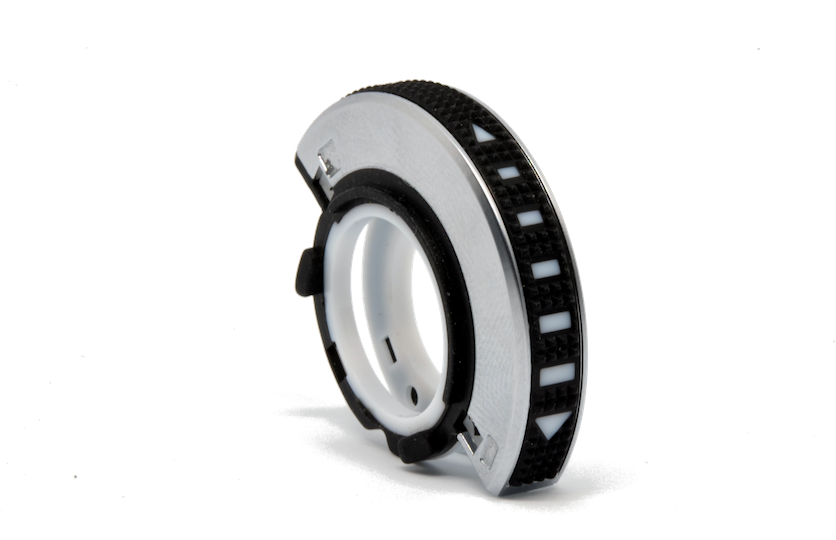

- usable in standard electroplating baths

- hardness of 40 Shore A to up to approx. 85 Shore A

- colourable in different colours

- allows numerous design options

(backlighting, …) - adhesion to all common electroplating hard materials (PC/ABS, ABS)

- hardness of 50 Shore A to up to 60 Shore A

- high tear strength under heat

- good demoulding capabilities

- UV-resistant and weather-proof

- no assembly stage thanks to 2K injection moulding

- hardness of 50 Shore A to up to 85 Shore A

- high flowability for long flow paths

- good scratch resistance

- UV-resistant and weather-proof

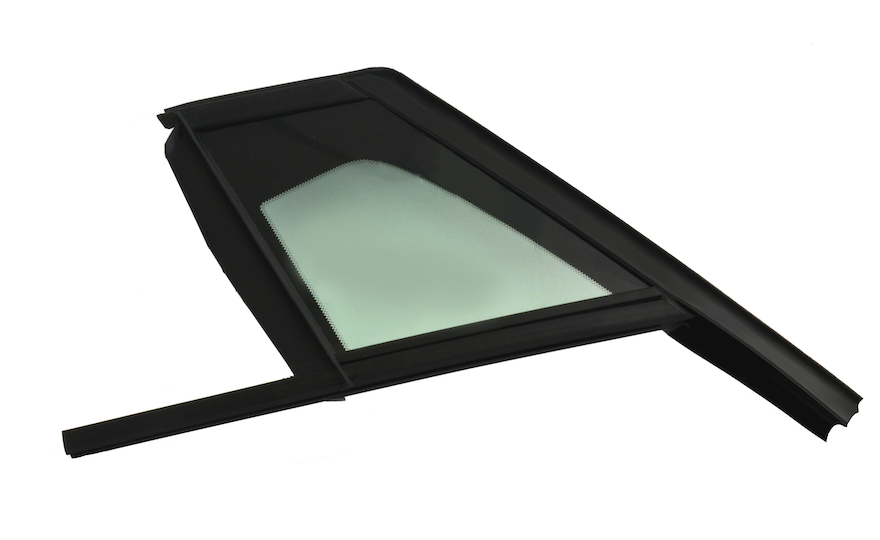

- support member made of PP

- hardness of 35 Shore A to up to 80 Shore A

- very high composite elongation at break

- high flowability,

- optimised for pane overmould

- excellent adhesion to EPDM

- also, adhesion to polar rubbers such as ACM, CR, …

- hardness 70 Shore A

- excellent fungus resistance

- tested food conformity

- high permeation density to O2 and CO2

- high resistance against suds and acids

- good plop behaviour

- Hardness in the Shore 00 range

- can be colored as desired

- high percentage of renewable raw materials possible

- physiologically harmless

- Hardness according to requirements

- not cytotoxic according to DIN ISO 10993-5

- dishwasher safe

- disinfectable

- Hardness approx. 70 Shore A

- colorable (leaves no marks on the floor)

- abrasion resistant

- also suitable for outdoor use